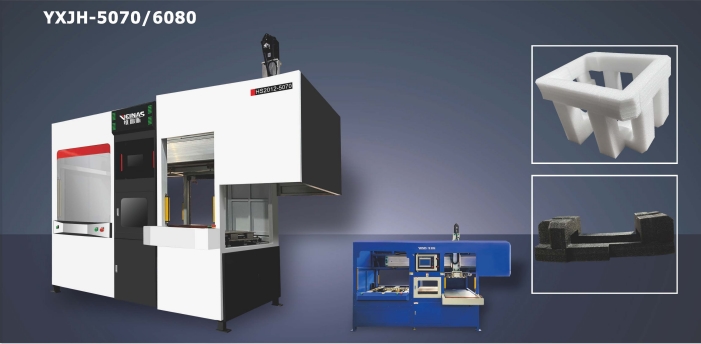

EPE Irregular Shaped Laminator

Application:

Automatically laminating irregular shape EPE bracket or EPE box, and widely used for packaging of air-conditioning and computer.

Performance advantage:

1. Energy saving, fast speed and high efficiency.

2. Laminated at a time in different directions (vertical/horizontal).

3. Use imported materials, high accuracy, good stability & durable. Controlled by multi-axis servo, imported electrical components and controller, running smoothly.

Working Principle:

The vertical lamination is done by upward and horizontal movement of vertical ironing board as well as the laminating work-station fixture, and then the clamping jaw grips the laminated part and moves onto the horizontal ironing station for heating and laminating into the integrity.

Parameter:

Model | Machine Size(mm) | Gross Power(KW) | Effective Machining Size(mm) | Net weight(T) |

YXJH-5070 | 3300*1260*2350 | 31 | 500*700*200 | 1.5 |

YXJH-6080 | 3700*1370*2750 | 33 | 600*800*200 | 1.9 |

Video:

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.