EPS polystyrene board equipment performance production process and use

by:Veinas

2021-07-25

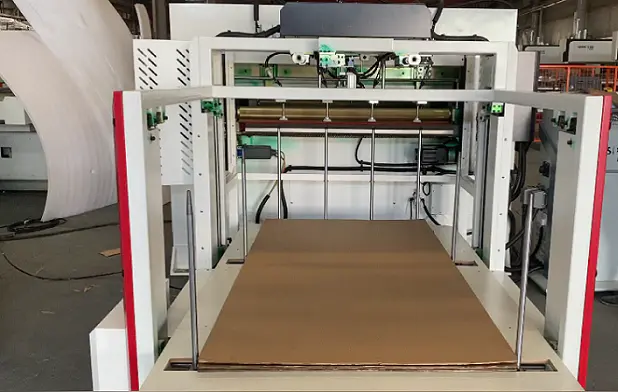

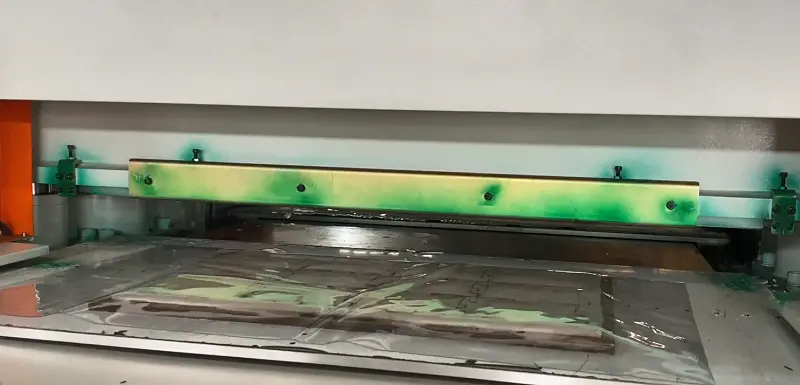

Expandable EPS molded polystyrene board is made of expandable polystyrene beads containing volatile liquid foaming agent, which is pre-heated and heated in a mold to form a white solid with a fine closed-cell structure. The shape is like the shockproof foam in the furniture we buy. Burning performance of graphite EPS polystyrene insulation board: reach B1 level (flame retardant); not only the flame retardant used for fire prevention of ordinary polystyrene board (which is volatile at high temperature), but also the infrared reflector mixed in the raw material. The fire resistance is stronger, more stable and reliable, and the fire resistance reaches the flame retardant B1 level, and it has good fire resistance. Main uses: 1>Used for building walls, roof floor heating, and color steel composite sandwich insulation board insulation; 2>Used for heat insulation materials for vehicles, ship refrigeration equipment and cold storage; 3>Used for decoration and carving Various models. 4>Used as a protective layer for the waterproof layer. EPS polystyrene board equipment includes EPS pre-foaming machine, vulcanization drying bed, EPS sheet forming machine and EPS foam cutting machine. Auxiliary equipment includes steam boilers, steam tanks, air compressors and air-conditioning tanks, storage bins and pipelines. EPS polystyrene EPE foam machine production process: 1. The first choice is to have a steam source (steam boiler or large boiler interface) 2. The EPS raw material is steam foamed through the foaming machine (temperature 80-110 ℃) 3. The bubble is passed through The storage bin is fully matured (temperature 25-40℃) 4. The matured material enters the plate forming machine for heating and forming 5. The formed plate enters the drying room to be fully shaped 6. Finally, the EPS foam cutting machine is used to size according to customer requirements To process and cut (0.6*1.2m, 0.6*0.6m, 0.5*1m, 0.5*0.5m and other sizes can be cut at will) The advanced high-end polystyrene board equipment has a long life, and the electrical uses famous brand electrical components, pneumatic components, valves, etc., and reliable quality , The production process adopts the German production process, which saves 20% of steam, and the product quality meets the international first-class foam product standards both inside and outside. The production speed is fast, and the fully automated operation saves labor costs. Quality is the foundation of the enterprise (please go around looking for low-priced polystyrene board equipment, what we do is quality) Since the establishment of the factory in Xinji, Hebei, Xinji Foam Machinery has continuously innovated on the road of development and is doing a good job Brand building is gradually carried out on the basis of management. The company has always adhered to the value innovation concept of high efficiency, high quality, and low energy consumption. The above is strictly implemented in accordance with the standards. The company produces more than 60 different specifications of polystyrene board equipment and foam molding machines, which are exported to more than 80 countries and regions. While expanding the sales network, it maintains close communication with customers. Our factory provides you with the best quality, most suitable price, and most comprehensive EPS polystyrene board equipment. We will provide you with the most professional and reliable equipment solutions and life-long service! In addition, the company also specializes in the production of Class A fireproof TPS real gold board equipment, XPS extruded board equipment, ICF module building equipment, FS composite insulation board equipment, homogeneous board equipment, special-shaped foam molding machine and foam weighting agent benzene board Insulation equipment and foam packaging equipment. EPS polystyrene board equipment performance, production process and use for more details. Advisory hotline: 15097461897

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd's has been able to achieve excellent performance in an extremely competitive industry.

For details on automation equipment manufacturer, see Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd at Veinas Machinery.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd deems automation equipment manufacturer as evolutionary rather than revolutionary. We've always had these 'social commerce' marketplaces in some form.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd's has been able to achieve excellent performance in an extremely competitive industry.

For details on automation equipment manufacturer, see Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd at Veinas Machinery.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd deems automation equipment manufacturer as evolutionary rather than revolutionary. We've always had these 'social commerce' marketplaces in some form.

Custom message