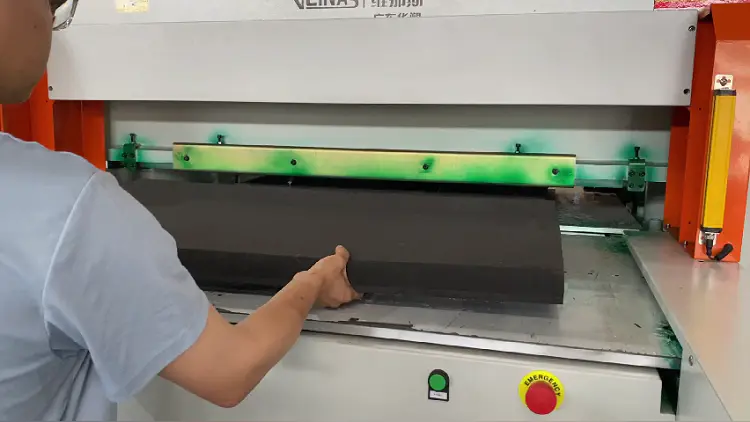

EPS foam machinery and equipment pre-foaming post-thread work

by:Veinas

2021-07-25

After the foam machinery equipment is pre-expanded, the beads retain a certain amount of foaming agent and water vapor. When they are out of the machine, they will condense and become liquid, and the liquid foaming agent will dissolve into the polystyrene to make the pressure in the bubbles very fast. When descending, there is negative pressure (some vacuum) in the bubble, and the beads are very soft and easily deformed. Therefore, when the air is sent, try not to make the wind pressure too large, the inner wall of the air pipe should be lubricated as much as possible, and the bending radius should be as large as possible (to reduce the collision resistance). The pipeline should be a good conductor of electricity. It is necessary to ground all the lines to prevent For static ignition, the transmission speed should not exceed 8m/s to prevent damage to the beads. The beads of the foam mechanical pre-expander just out of the machine are all wet. After being released from the pre-expander, it absorbs air and suddenly encounters cold, causing the foaming agent in the honeycomb cells to condense and form a negative pressure in the cells, so the beads are in It is necessary to place it for a period of time after the pre-expansion, on the one hand to make it dry, on the other hand to infiltrate the air to eliminate the negative pressure, balance the internal pressure and external pressure in the cells, avoid collapse of the cells, and make the beads elastic. The process of drying, cooling and stabilizing the cell pressure of the EPS beads just out of the pre-expander is called maturation. Maturation improves the further expansion of the pre-expanded beads in the molding process, the sinterability between beads and the elasticity of the beads, which is beneficial to improve the quality of EPS products. During the maturation process, the beads are cooled by air, and the foaming agent and water vapor in the pores of the cells are condensed into liquid, so that a negative pressure is formed in the cells. At this moment, air penetrates into the cell through the cell membrane to balance the pressure in the cell with the external pressure, which will make the pre-expanded beads elastic. The maturation can be divided into two methods: natural maturation and pressure maturation. 1. Under cool, dry, and ventilated conditions, allowing natural aeration is called natural maturation. 2. Add gas (air, nitrogen) to the pre-expanded beads after natural maturation to make them have a certain pressure and inflate it, which is called pressurized maturation. More technical details of EPS foam machinery: Technical consultation hotline: 15097461897 (WeChat synchronization)

This is an internationally recognized standard which acts as a form of guarantee that everything Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd does is managed to the highest quality standards.

No, this isn't a wonder product and it won't be likely to change your life but it will give your machine manufacturer a kick and bring the extraordinary to the every day. give it a shot at Veinas Machinery.

The global market is estimated to reach a value of almost machine manufacturer in the next decade. have a robust position in the machine manufacturer market because of its proven high potency in machine manufacturer.

This is an internationally recognized standard which acts as a form of guarantee that everything Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd does is managed to the highest quality standards.

No, this isn't a wonder product and it won't be likely to change your life but it will give your machine manufacturer a kick and bring the extraordinary to the every day. give it a shot at Veinas Machinery.

The global market is estimated to reach a value of almost machine manufacturer in the next decade. have a robust position in the machine manufacturer market because of its proven high potency in machine manufacturer.

Custom message