eps foam building module equipment motor_maintenance principle of foam molding machine

by:Veinas

2021-07-30

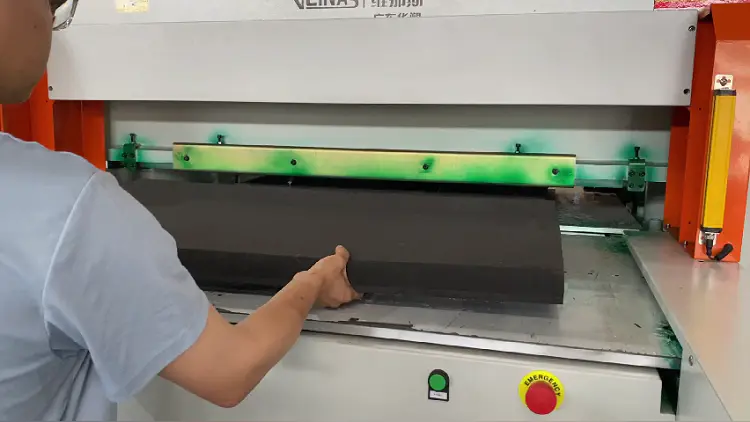

Huasu is a well-known company that provides silicon polystyrene EPE foam machine and other products and services in China. I hereby introduce you to the company’s related content and learn from each other. The production process of eps foam building module equipment has great energy-saving potential. Take the machine as an example, the process of an injection molding machine is generally divided into several stages, such as clamping, injection, melting, holding pressure, cooling, and mold opening. Each stage requires different pressure and flow. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide appropriate oil pressure at various stages of injection molding machine production, and reduce energy loss to the greatest extent. Some end users were the first to use frequency converters in eps foam building module equipment. The system integrator provided them with frequency conversion energy-saving transformation schemes for eps foam building module equipment. The effect of the foam was remarkable, and the motors of eps foam building module equipment became more and more. Many eps foam building module equipment users have adopted frequency converters to transform their equipment. More attention: Foam molding machine is a kind of equipment for processing materials required by the chemical industry such as foam and sponge. At present, the laser machine is mainly used for cutting. Due to the advantages of laser beam fine cutting, such as not easy to deform, smooth cutting, and no edge, it is currently used in various fields. Of course, it is inevitable that there will be failures during the use of the foam cutting machine and need to be overhauled. Now let's talk about the following precautions during overhaul. Only personnel who know how to use and operate are allowed to repair machinery or replace components! In order to prevent accidents or damage to the machine, the following principles must be observed during maintenance: 1. When a fault occurs, disconnect the power supply to stop the machine; 2. When the machine cannot be used normally, check the relevant manuals and use Instructions to determine the correct measures to be taken; before overhauling or replacing components, the power supply eps must be turned off. The maintenance principle of the foam molding machine 3. The parts (components) removed during the maintenance should be replaced with the same new parts (components) in situ, and the instruments used in the maintenance must be calibrated; 4. It is strictly forbidden to put flammable or metal objects Left in the electric cabinet or junction box; 5. Regularly check the cables and wires for damage to prevent leakage or electric shock. Well, about the 'maintenance principle of foam molding machineTelephone consultation, of course, you can also consult our customer service online!

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is a company that offers a wide selection of . OEM and ODM services are also available to users. To know more, go to Veinas Machinery.

See reviews of the latest trend in automation equipment manufacturer industry at Veinas Machinery, and see the best that work in just minutes! Visit us right away!

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd employs a group of professional staff, enhancing the function of automation equipment manufacturer.

automation equipment manufacturer can also provide a new, productive option for business owners, if you're willing to use it.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is a company that offers a wide selection of . OEM and ODM services are also available to users. To know more, go to Veinas Machinery.

See reviews of the latest trend in automation equipment manufacturer industry at Veinas Machinery, and see the best that work in just minutes! Visit us right away!

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd employs a group of professional staff, enhancing the function of automation equipment manufacturer.

automation equipment manufacturer can also provide a new, productive option for business owners, if you're willing to use it.

Custom message