Energy-saving potential of eps foam building module equipment_foaming process of benzene board machinery

by:Veinas

2021-07-29

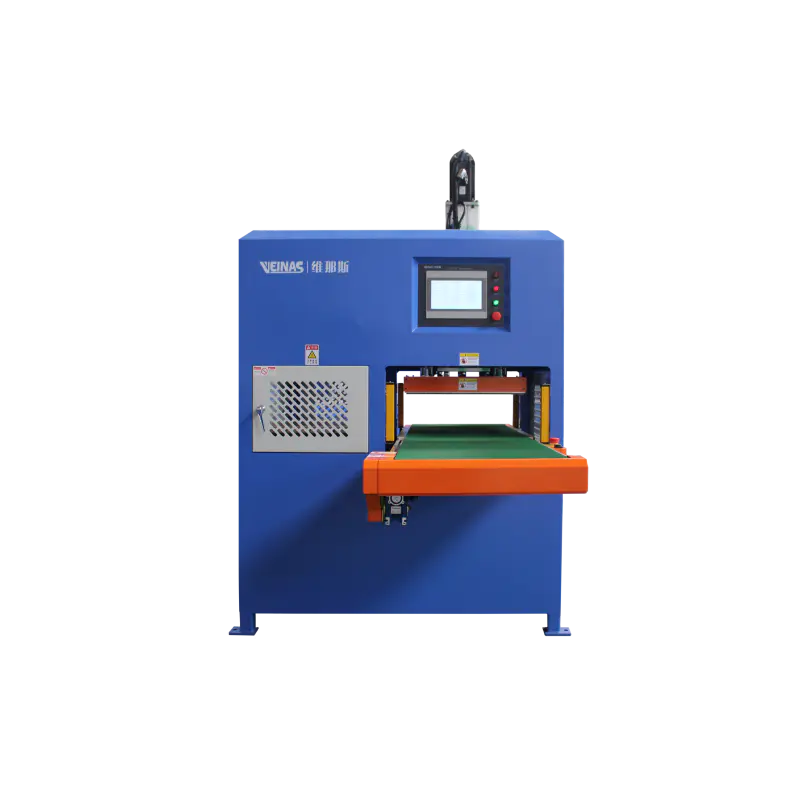

Huasu is very professional in the foaming process of EPE foam machine. Today, our editor will introduce you to the foaming process of benzene board machinery. We hope that through our introduction, you will have a deeper understanding of the foaming process of benzene board machinery. Understand that the production process of eps foam building module equipment has great energy-saving potential. Taking injection molding machine as an example, the process of injection molding machine is generally divided into clamping, injection, melting, holding pressure, cooling, mold opening, etc. Stages, each stage requires different pressures and flows. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide appropriate oil pressure at various stages of injection molding machine production, and reduce energy loss to the greatest extent. Some end users were the first to use frequency converters on eps foam building module equipment. The system integrator provided them with frequency conversion energy-saving transformation schemes for eps foam building module equipment. The effect is remarkable. eps, the energy saving potential of eps foam building module equipment is increasing. Many eps foam building module equipment users have adopted frequency converters to transform their equipment. Welcome to read: Benzene board mechanical foaming machine first appeared in foreign countries. Its original model used impeller to rotate at high speed to make foam, so it is also known as 'foaming machine'. Later, with the continuous advancement of technology, the technical content of the foaming machine continued to increase, and new models continued to appear, forming a different technical system. That is, the foaming agent is directly added to the mortar mixer or concrete mixer, and the foaming machine and the mortar or concrete are mixed together to generate foam. Later, around the 1970s, dedicated foaming machines, namely high-speed impeller foaming machines, began to appear. It is impossible for the benzene board mechanical foaming machine to produce foam out of thin air. It introduces air into the foaming agent aqueous solution to uniformly disperse it to achieve the largest possible contact interface between liquid and gas, so as to make the surface active substances in the foaming agent. An electric double layer is formed on the surface of the liquid film and surrounds the air, forming individual bubbles. Therefore, the foaming machine is also equivalent to the foaming machine. It is equivalent to mixing the foaming agent aqueous solution with air to form bubbles. The main body of foamed concrete is foam, so the foaming machine for making foam has become the key equipment and main machine for the production of foamed concrete. Without the foaming process of foaming and EPE foam machine, there would be no foaming concrete. The content introduced in the above 'Foaming Process of ' is about the introduction of foam box production equipment. After reading our article, if you know more about foam box production equipment, plastic foam box production equipment, etc. Interested, please click on our product list to view one by one.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has famous reputation in worldwide.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is one of China's biggest providers in the following categories of products: automation equipment manufacturer, machine manufacturer, machine manufacturer,etc. We also welcome ODM and OEM orders, and offer the highest standards of service, the cheapest deals, and the best buying experience. Get to know us at Veinas Machinery.

Though the cost of these sustainability initiatives as automation equipment manufacturer can be high, harnessing the power of an ethical supply chain to appeal to conscientious consumers can be a smart move both ethically and financially.

automation equipment manufacturer receives the updates through industry associations, internal legal counsel, regional associations and legal publications.

Getting automation equipment manufacturer from an idea to production is a complex process. It involves significant research, time, planning and patience. But with the right information, the right resources and the right product, it's possible.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has famous reputation in worldwide.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is one of China's biggest providers in the following categories of products: automation equipment manufacturer, machine manufacturer, machine manufacturer,etc. We also welcome ODM and OEM orders, and offer the highest standards of service, the cheapest deals, and the best buying experience. Get to know us at Veinas Machinery.

Though the cost of these sustainability initiatives as automation equipment manufacturer can be high, harnessing the power of an ethical supply chain to appeal to conscientious consumers can be a smart move both ethically and financially.

automation equipment manufacturer receives the updates through industry associations, internal legal counsel, regional associations and legal publications.

Getting automation equipment manufacturer from an idea to production is a complex process. It involves significant research, time, planning and patience. But with the right information, the right resources and the right product, it's possible.

Custom message