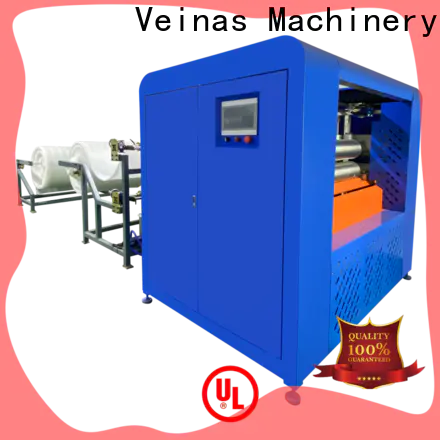

Parallel Thickening Machine

Mainly used for the composite thickening of the EPE, EVA, IXPE, ect.

Feeding materials by servo-controlled transferring line and heating by multi-head air knives, to laminate the upper and lower layers of EPE by the roller.

Hight flexible and more stable.

Hi-degree automation , less manpower and high efficiency.

Suitable for different thickness and sizes of EPE in thickening.

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.