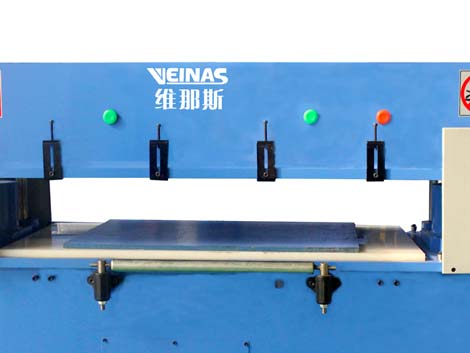

Company Advantages1. The inspection of Veinas hydraulic sheet cutting machine is strictly performed. All incoming materials (hardware, components ) is thoroughly inspected for material condition, special process specification, and chemical composition.

2. hydraulic cutter is characterized by hydraulic sheet cutting machine as well as better capabilities of hydraulic angle cutting machine .

3. hydraulic cutter is good at all working conditions with hydraulic sheet cutting machine and longer life span.

4. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has large-scale integrated processing plant for hydraulic cutter .

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

SYCD-100T1 | 100T | 3000*2300*1570 | 700*1200 | 7.5 | 50-240 |

SYCD-100T2 | 100T | 3000*2300*1570 | 700*1400 | 7.5 | 50-240 |

SYCD-100T | 120T | 3000*2300*1570 | 700*1400 | 11 | 50-240 |

1

Applications

Special for blister and PS foam products such sa disposable food container, cup cover, fresh/sea food tray, fruit box, etc.

2

Performance Advantages

Special device of cutting die and stacking tools in one machine,highly increases the output and saving cost and labors.

With automatic guide rail connecting feeding, cutting and stacking processes, running fast, easy to operate.

Controlled by PLC with touching screen, to set and micro-adjust working pressure, cutting depth, feeding speed easier, faster and more precise.

Auto-balance structure of double-cylinder, four-column and self-balance connecting rod, makes sure equal pressure in any working area.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is recognized as one of the most reputable manufacturers in China. We specialize in the development, design, and production of hydraulic sheet cutting machine .

2. We have good supervision of production for hydraulic cutter .

3. We strive to prevent and reduce environmental pollution during our production. We utilize appropriate technologies in our design and manufacturing process. We make efforts to eliminate waste in every stage of our operations. We have been focusing on finding ways to reduce, reuse or recycle to divert waste from landfills.