Company Advantages1. During the production of Veinas punch press machine , it adopts a fully automatic sorter machine to screen and classify predictive parameters such as voltage, wavelength, and brightness.

2. The product has stable operating pressure. During the operation, the pump depletion phenomenon is eliminated to avoid dry friction or damage to sealing.

3. It is characterized by good mechanical sealing performance. It is required to check the sealing capability thoroughly and has to pass the static pressure test to guarantee no leakage problem.

4. The product is widely praised for their easy usage and distinguished features.

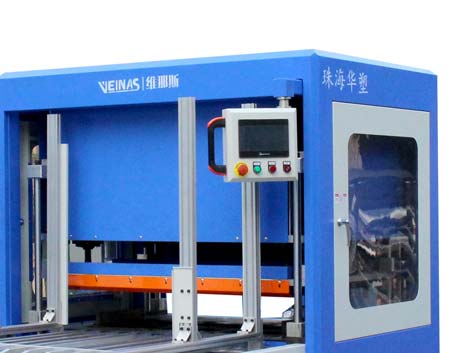

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

CXJ-6080 | 2200*1060*1900 | 3 | 800*600 | 1.5 | 1.5 |

CXJ-12065 | 2400*1560*2050 | 4 | 1200*650 | 2 | 1.8 |

1

Applications

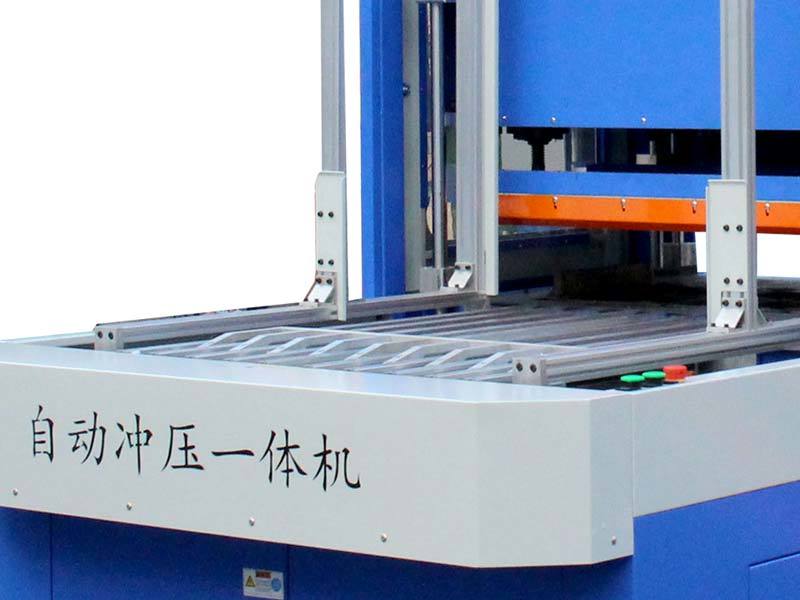

Successive feeding available, and one-time completion for cutting, punching and discharging at the same work-station.

2

Operation Principles

For long or rolled EPE, it could be done by a combination of continuously pulling, punching, cutting, and waste-discharging. In turn, the waste is squeezed out from the cavity of the die. Three processes are completed at one time with hi-efficiency.

3

Performance Advantages

Die-cut punching and waste-discharging into the integrated shape. Lowest labor intensity and highest production efficiency. Mainly used for EPE mass production.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is a creator, engineer, and problem solver. We are passionate about the R&D and manufacture of punch press machine .

2. foam hole punch technology is performed by our experienced technicians to make sure the quality of hydraulic

punching machine .

3. We are active in some charitable foundations. We are working hard to reduce poverty and creating better education opportunities by donating capitals on building village schools. Understanding the importance of environmental sustainability, we have set the ecological goal of preventing contamination of our local environment.