Company Advantages1. Veinas hydraulic shear cutter must go through the necessary tests. It will be tested in terms of insulation resistance, current leakage, and current load.

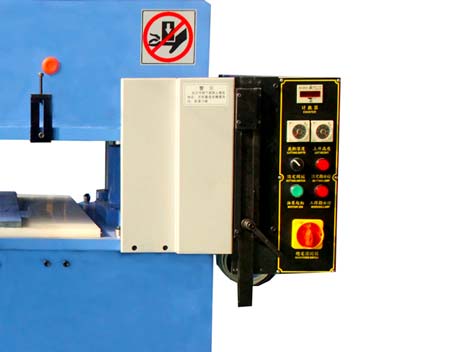

2. The product is safe in use. It is built with the proper safety devices in place, including an emergency stop button and curtain guards.

3. The product responds quickly in a short period of time. It can run high-performance control programs with fast processing and no latency.

4. Paying attention to the quality assurance of

hydraulic shearing machine will facilitate Veinas to develop better.

5. Our hydraulic shearing machine is highly recommended by customers for its high reliability.

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

HS-30T1 | 30T | 2330*1320*1260 | 610*1600 | 2.2 | 50-160 |

HS-30T2 | 30T | 1950*1320*1260 | 610*1220 | 2.2 | 50-240 |

HS-30T3 | 30T | 2330*1320*1260 | 610*1600 | 2.2 | 50-240 |

HS-40T1 | 40T | 2330*1320*1260 | 610*1600 | 4 | 50-160 |

HS-40T2 | 40T | 1950*1320*1260 | 610*1220 | 4 | 50-240 |

HS-50T1 | 50T | 2330*1320*1260 | 610*1600 | 4 | 50-160 |

HS-50T2 | 50T | 1950*1320*1260 | 610*1220 | 4 | 50-240 |

1

Applications

Suitable for shoes, bags, handbags, mobile phone sets, seats, masks, plush toys, sponges, silk flowers, EPE, EVA, plastic and other packaging products and abrasives.

2

Performance Advantages

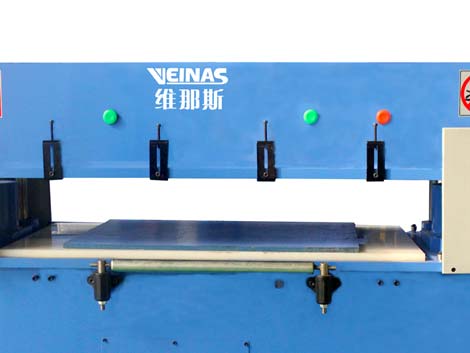

1.Auto-balance structure of double-cylinder, four-column and self-balance connecting rod, makes sure equal pressure in any working area.

2.Slow down when the cutting die touches material, to fonfirm the precision between upper and bottom for thick materials.

3.Stroke adjustment device, makes stroke simple and correct to adjust with cutting die, cutting board and materials.

4.Central automatic lubrication system, increases machine durability,prolong the working time.

5.Suitable for single-layer or multi-layer sheet or roll materials.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has long been committed to the R&D and production of hydraulic shearing machine .

2. The company has built up a clear and worthy customers base. We have carried out researches aiming to identify the targeted customers, cultural backgrounds, geographic locations, or other characteristics. These researches definitely help the company gain a deeper insight into their customer groups.

3. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd carry forward hydraulic shear cutter and make hydraulic cutter price as its eternal goal. Inquire now! Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd strives to structure hydraulic angle cutting machine as its service notion. Inquire now!